NLG-0001

페이지 정보

본문

|

|

|

|

| 1. Exhaustive cost reduction efforts through standardization have

resulted in the world's top-level Rotogravure press with a low price. 2. A wide range of models is included in the series : 4 models by speed and printing width,respectively. Sectional drive available. Water-base ink models available. 3. New design. 4. Various new devices and models are standard specifications. 5. Control panels of a new design have improved operability significantly. 6. Smaller footprint due to: Integrated turret design / Local control boards / No preset and color control panels. 7. Preset function is a standard specification: 16 preset items. Color control data can also be preset. |

|

|

|

|

|

|

|

|

|

|

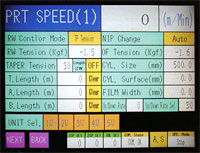

| Easy to use: (1) The machine is controlled and set on any printing unit to eliminate operator walk-around time. (2) Essential functions are button-controlled while nonessential ones are left out on the panel to improve operability. Merits of digitization: (1) Improved accuracy in machine operation. (2) Many data are preset. Merits of touch panel: (1) Easy-to-read visual display. (2) The same procedure is used to select and set a variety of data. (3) Fewer control buttons. (4) Easy to handle operation data with digital values. (5) Various high-level settings. Decentralized control board (1) Elimination of installation space. (2) Elimination of wiring(reduced installation time). |

|

|

|

|

|

|

|

|

|

| MODEL | NLG15 |

NLG20 |

NLG25 |

NLG30 |

| <GENERAL SPECE> | ||||

| Printing Capacity (m/min.) | 150 |

200 |

250 |

300 |

| Web Width (mm) | 1000,1100,1200or1300

| |||

| Guide Roll Width (mm) | Web Width+100 |

|||

| Frame Thickness (mm) | 70 |

|||

| Plate Cylinder Circumference (mm) | 400 to 900 |

|||

| Plate Cylinder Mounting | Shaftless |

|||

| Printing Cylinder Center Height (mm) | 850 from floor |

|||

| Ink Supply to Cylinder | Furnisher System |

|||

| Pressure Roll Elevation | Vertical Elevation |

|||

| Pressure of Printing Plate (Kg) | 50 to 300 |

|||

| Compensator Device | Compensator Roll System/Adjust range

of Max.Paper pass:1000mm/Digital shows Compensating position |

|||

| Side-Lay | Motorised with Digital Indicator |

|||

| <DRYER> | ||||

| Type | Hot Air Blowing Nozzles with Guide

Rolls |

|||

| Source | LPG(or Steam) |

|||

| Dumper | Pneumatic |

|||

| Nozzle (Set) | 6 |

8 |

10 |

14 |

| Blower <Air Volume> | 30 to 38 |

40 to 50 |

50 to 63 |

64 to 82 |

| Blower <Static Pressure> (mmAq) | 250 |

|||

| Blower<Output> (kW) | 3.7 |

5.5 |

5.5 |

7.5 |

| Cooler (Right after the dryer) | Water Cooling Roll |

|||

| <UNWIND/REWIND> | ||||

| Type | Turret with double shafts |

|||

| Max.Unwind/Rewind Diameter(mm) | 600 |

|||

| Paper Core for Unwind/Rewind(Standard) | 3" |

|||

| Web Mounting | Shaftless |

|||

| Web Splicing | Automatic |

|||

| Web Cutter | Automatic |

|||

| Tension (Kg) | 3 to 20(*1) |

3 to 20(*1) |

3 to 20(*1) |

3 to 20 |

| <POWER DRIVE> | ||||

| Main Motor for 5 colors (kW) | AC11 |

AC11 |

AC11 |

AC15 |

| Main Motor for 5 colors (kW) | AC11 |

AC15 |

AC15 |

AC15 |

| Main Motor for 6 colors (kW) | AC15 |

AC15 |

AC15 |

AC18.5 |

| Main Motor for 7 colors (kW) | AC15 |

AC18.5 |

AC18.5 |

AC22 |

| Main Motor for 8 colors (kW) | AC18.5 |

AC18.5 |

AC22 |

AC30 |

| Main Motor for 9 colors (kW) | AC18.5 |

AC22 |

AC30 |

AC37 |

| Main Motor for 10 colors (kW) | AC22 |

AC30 |

AC30 |

AC37 |

| Unwind Moter (kW) | AC2.2 |

AC3.7 |

AC5.5 |

AC7.5 |

| Infeed Motor (kW) | AC1.5 |

AC2.2 |

AC3.7 |

AC5.5 |

| Outfeed Motor (kW) | AC1.5 |

AC2.2 |

AC3.7 |

AC5.5 |

| Rewind Motor (kW) | AC2.2 |

AC3.7 |

AC5.5 |

AC7.5 |

| Turret Motor for Unwind/Rewind (kW) | AC0.75 |

|||

| <DEVICE>Initial Positioning by Auto Calculation

with Plate Cylinder Circumference and lateral way also available. Color Control,EPC,Stroboscope,Pre-Heater,Preset System,Blower for Print Plate,Cooling Blower,Dryer for Control Air,Connector for Viscosity Check,100V socket,Lighting 40W inside of machine, |

||||

| <OPTION>Monitor Display,Mis Detector,Turn Bar Device,Automatic Setting of EPC Sensor,Rewinder Touch Roll,Stroboscope for each unit,Electro Statics Eliminator(Iorizer Type),Reverse cutter,Re-heater,Air Purge,Overrun Stopper(Paper Break Detector),Handcart for Print Plate,Handcart for Material,Ink Circulation Pump,Viscosity Controller,System for Water base ink,Sectional Drive. | ||||

| *1:Possible to have 30Kg along with motor capacity |

서울시 강동구 풍성로 237 (둔촌동 518-5, 신라빌딩) Tel: 02-489-1953~5, 1934~7 Fax: 02-489-2152 Mail: silla@newlong.co.kr

서울시 강동구 풍성로 237 (둔촌동 518-5, 신라빌딩) Tel: 02-489-1953~5, 1934~7 Fax: 02-489-2152 Mail: silla@newlong.co.kr