3CM-5BG / 3CM-5BGEH / 3CM-5AG

페이지 정보

본문

Economically designed gross weighing and Bagging System.

Direct filling granular products by gross-weighing system in which filling and weighing are done at the same time. Designed to place bags at fill-chute directly by swing type feeder. Easy operation and maintenance.

Catalog Download

| Capacity (bags/hour) | Max. 120* (sewing machine speed is 8m/min.) |

|---|---|

| Bag size (mm) | L650~850✕W400~440✕GW76 (paper bag 3~4ply) |

| Filled weight (kg) | 25 (20~30) |

| Machine weight (kg) | Approx. 700 |

※Depends on products and bag size.

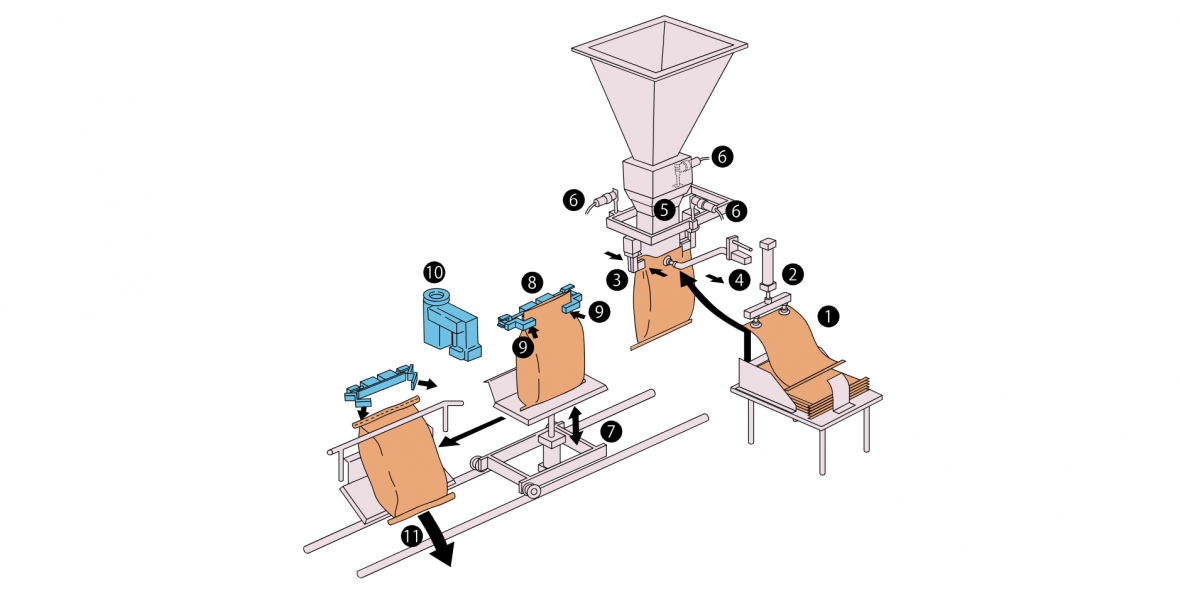

MACHINE CONSTRUCTION

| (1)Bag feeder | 50 bags are set on the bag magazine, where the bag mouth is placed at the main body side. |

|---|---|

| (2)Bag pick-up section | The bag is picked-up one by one and turned in 90°toward filling section. |

| (3)Bag clamp section | The both side of the bag is clamped. Automatic bag detector confirms the right position of the bag clamp. |

| (4)Bag opening section | After bag opening by vacuum cup, it will remove away from the bag. At the same time, bag clamp closes each other. Vacuum generator is used for vacuum operation. |

| (5)Filling section | Expanding spout fills products smoothly into the bag. Bag clamp spread out bag at both gusset of the bag after filling finishes. |

| (6)Weighing section | Three load-cells suspend bag clamp and filling section.The automatic zero adjustment is done on the empty bag. |

| (7)Bag carrier, bag bottom tapper | When filling products, bag carrier moves to filling section and bag bottom tapper lifts up the bag bottom to accelerate the filling products. |

| (8)Bag former | After the bag is spreaded, press bars at filling section and bag carrier form good shape of the bag. |

| (9)Bag clamp finger | The clamp bag is carried to sewing machine after bag forming. |

| (10)Bag sewing machine (Model DS-6AC) | Detecting the bag, the sewing machine operates and bag clamp fingers are released. Detecting the end of the bag, the sewing machine stops. |

| (11)Discharging | Bag carrier runs and stops at the fixed position, then the bag is discharged by inclined tapper plate. |

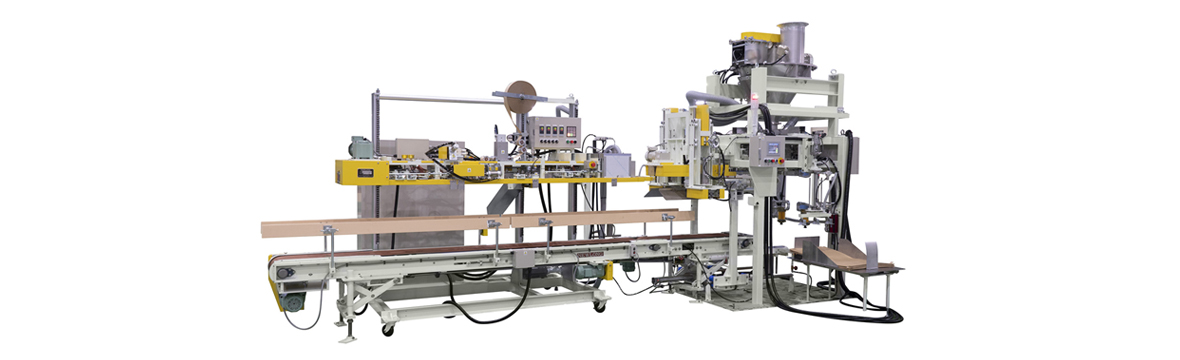

3CM-5AG (지대이송 콘베아 부착타입)

3CM-5AG Bag Conveyor Type

An automatic machine sealing device can be connected to the compact body of the 5BG

| Maximum capacity (bags/hour) | max.130 bags*1 |

|---|---|

| Bag Material | Kraft paper bag, PE bag, inner layer PE*2 |

| Bag specification (mm) | 650~850 Length × 400~440 Width × 76 Gusset Width |

| Bagging weight (kg/bag) | 20~30kg |

| Weighing accuracy | ± 1/1000 (at 25kg)*1 |

서울시 강동구 풍성로 237 (둔촌동 518-5, 신라빌딩) Tel: 02-489-1953~5, 1934~7 Fax: 02-489-2152 Mail: silla@newlong.co.kr

서울시 강동구 풍성로 237 (둔촌동 518-5, 신라빌딩) Tel: 02-489-1953~5, 1934~7 Fax: 02-489-2152 Mail: silla@newlong.co.kr